POSITION:HOME>Industry dynamic

Aluminum profile automation equipment in the production proc

CLICK:117TIME::2021-07-12 10:22

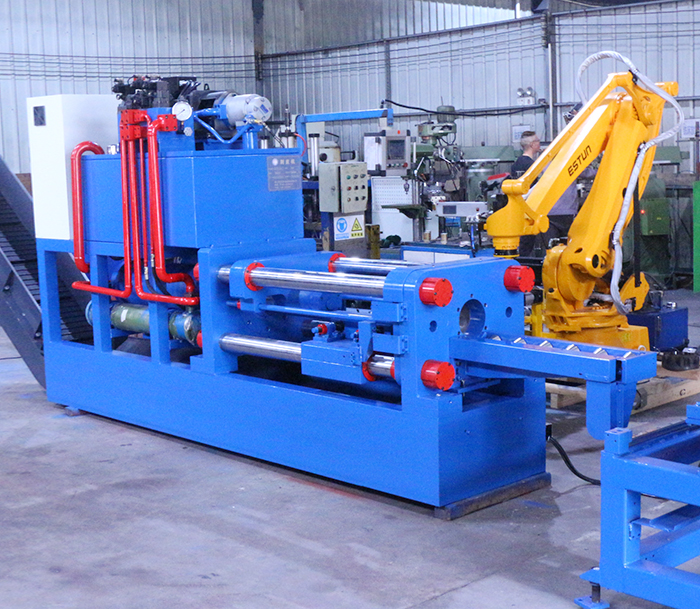

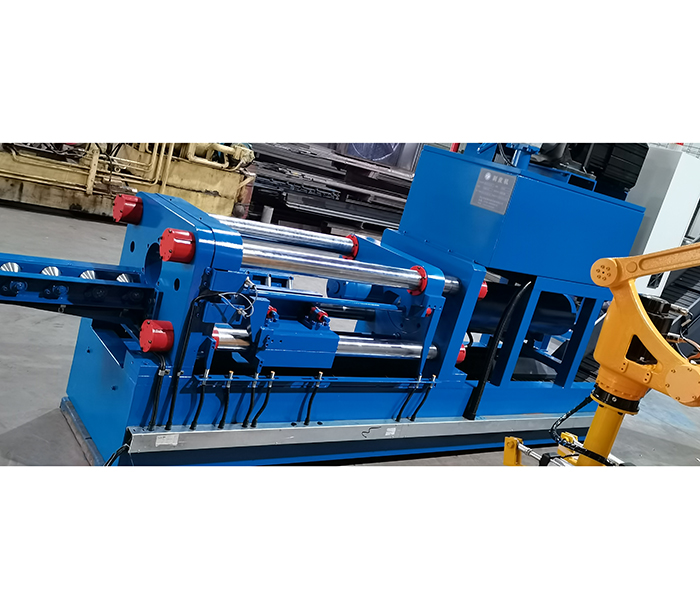

Aluminum profile automation equipment is a benefit to everyone's products, please look below, here to sort out, a lot of knowledge about aluminum profile automation equipment, convenient for everyone to understand quickly, its aluminum profile frame connection, can be free multiple disassembly, and does not affect the use of aluminum profile automation equipment, Connection mode is also flexible, changeable, easy to everyone's transportation. Let everyone more quickly to complete the work, made a favorable contribution, and make the aluminum profile automation equipment becomes more convenient.

The advantages and disadvantages of the aluminum profile chassis of automation equipment compared with the Fangtong frame: the aluminum profile rack done on the market is basically processed and assembled by 6063 industrial aluminum profile, and the advantages of the mechanical protective cover relative to the iron frame made by industrial aluminum profile are as follows:

1, aluminum alloy density is low, but the strength is relatively high, close to or better than good steel plastic good corrosion resistance, whether it is suitable for application in dry or wet environment.

2. The connection mode of industrial aluminum frame can be freely dismantled and unloaded for many times, and the connection mode is flexible, changeable, simple, and easy to transport.

3, industrial automation equipment aluminum chassis relative to the iron frame is more grade, improve the overall mechanical equipment external image and gas field and so on. The disadvantage of the relative iron frame cost is slightly higher, bearing capacity is not as good as the iron frame, at present, China's large equipment with iron frame or more, small and medium-sized and high and middle mechanical frame is gradually using aluminum frame to replace the iron frame.

Automatic equipment aluminum chassis can be designed according to customer requirements, with aluminum profile, baking paint sheet metal, stainless steel plate, acrylic plate, PVC plate and other materials, supplemented by a complete modular parts series, According to the design requirements and the process can quickly structure a variety of semiconductor equipment, photoelectric equipment, dispensing equipment, electronic equipment, lithium battery equipment and automatic mechanical equipment automation equipment aluminum chassis.

Automation equipment aluminum chassis must take put down gently, in the process of handling fight knock against, lest cause bruise on the surface, the problem such as deformation, automation equipment in the process of aluminum chassis production cutting, milling, hole and tapping process pay attention to the reasonable place aluminum extrusions, and clean up the impurities such as scrap metal processing equipment mesa, In the process of assembling automation equipment aluminum case, unless necessary, try not to tear off a layer of protective film outside the aluminum profile, otherwise, in the process of assembly may be because of contact with the assembly table or material and scratch industrial aluminum profile.

This shows that the aluminum profile automation equipment is a good equipment worth using, and the shield of the machine is different from the iron frame, which has great advantages. It is better than good steel and plastic with good corrosion resistance. It is suitable for application in dry or wet environment. It is convenient for us to work more quickly and complete the tasks in our hands more confidently. In a word, aluminum profile automation equipment is in line with the needs of everyone now.

Ranking

- Aluminum profile automation equipment in the production proc

- How to know the pros and cons of industrial aluminum profile

- Aluminum profiles should be cooled to a certain temperature

- What is a precision automatic saw?

- Aluminum profile automation equipment factory to remind you

WeChat

WeChat